| Core Components | PLC |

| Weight | 3000 kg |

| Key Selling Points | Easy To Operate |

| Machinery Test Report | Provided |

| Raw Material | Galvanized Sheet |

| Power(W) | 5KW |

| Place of Origin | Fujian, China |

| Warranty | 2 Years |

| Video outgoing-inspection | Provided |

| Brand Name | XHH |

| Selling Units | Single item |

| Single gross weight | 0.500 kg |

| Single package size | 100X30X5 cm |

Computer-controlled fully automatic changeover, no manual adjustments required, can easily switch types in just 1 minute to achieve the desired product specifications.

Manual changeover of C/Z takes only half an hour.

Automatic alignment adjustment at the feed inlet, hydraulic punching can automatically punch waist edge holes/bottom edge holes/double holes/single holes, and automatically cut to fixed lengths with precise accuracy.

Fast forming speed, producing boards at 25-30m/min, ensuring no trumpet buckles in the finished board types, giving a beautiful vertical angle, and can easily press board thickness of 3.0mm without putting stress on the equipment, wear-resistant and pressure-resistant.

Saves labor costs and increases production efficiency.

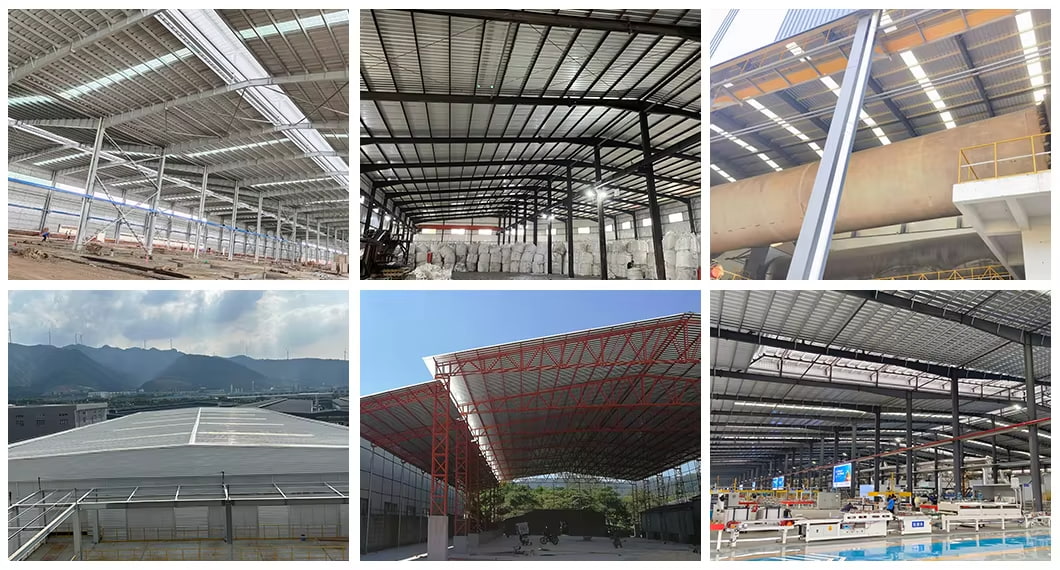

Purlins are the main load-bearing structures of medium to large industrial and civil buildings, such as steel structures, workshops, warehouses, exhibition halls, theaters, sports venues, and market flower tent roofs.

Benefits of using a Metal CZ Channel Roll Forming Machine are as follows:

Metal CZ Channel Roll Forming Machines are frequently employed in the construction, automotive, aerospace, and manufacturing sectors. They are essential for producing structural components and various building materials.

OUR SERVICE:

1. Factory Lifetime Service:offer technical support for the entire life of our machines.

2. Customized Profile:can design the profile according to customer request.

3. ONE-YEAR Guarantee Period:we could supply you the replacement parts free of charge for any damaged parts caused by quality problems.

4. Overseas Services Optional:we can send our technicians to install and train the workers in the clients' factories with extra cost.

To explore more machines, please browse our comprehensive selection here.