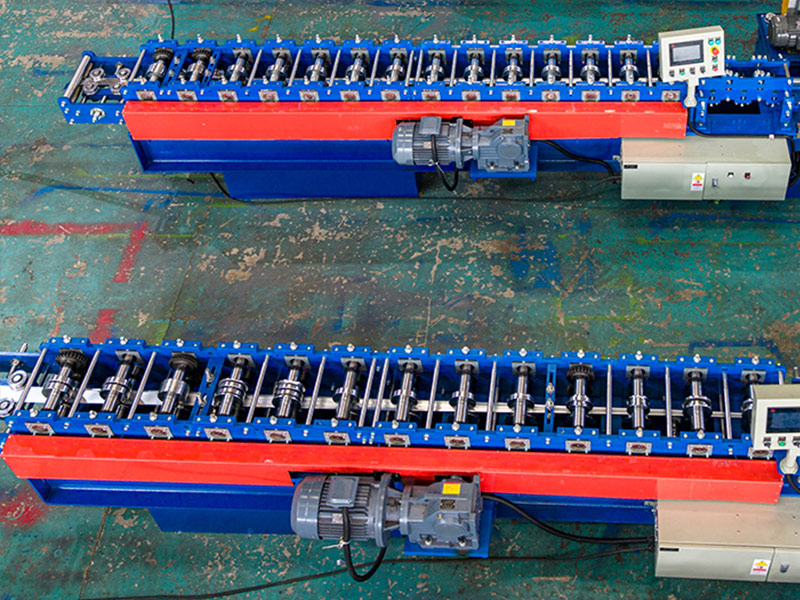

Create U-shaped channels or profiles from metal coils or sheets.

Molding a continuous strip of metal by guiding it through a sequence of rollers to progressively achieve the intended profile.

Specifications:

| Item | Specification |

| Overall Dimensions | 5000 × 800 × 1500 mm |

| Weight | 2000 KGS |

| Motor Power | 5.5 KW |

| Hydraulic Power | 3 KW |

| Voltage | 220V / 60Hz / 3 Phase |

| Forming Stations | 12 Stations |

| Forming Speed | 0–45 m/min |

| U-Channel Height | 12 mm |

| U-Channel Width | 38 mm |

| Material Width | 60 mm |

| Material Thickness | 0.3–0.6 mm |

| Material Type | Galvanized Steel |

| Cutting Tolerance | ±2 mm |

| Roller Material | Cr12 steel, heat-treated, polished and hard chrome-plated |

| Shaft Material | 45# Steel |

| Sprocket Material | 45# Steel, high-frequency quenched |

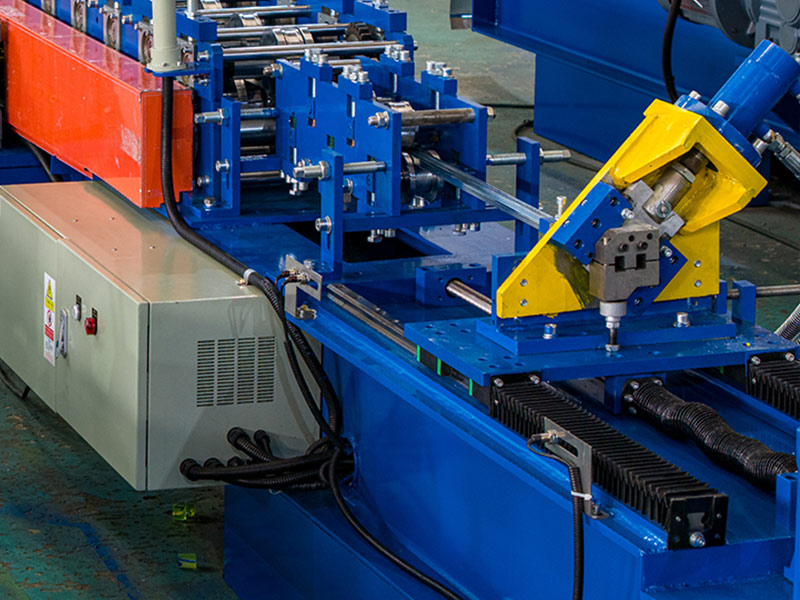

| Cutting System | Hydraulic Cutting Device |

| Blade Material | Cr12, quenched at 60–62°C |

| Frame Material | High-quality welded structural steel |

| Raw Material | Galvanized Steel |

An overview of the operation of a U Channel Roll Forming Machine is as follows:

Material Feeding

The process initiates with a coil or sheet of metal, typically steel or aluminum, which is positioned on a decoiler or uncoiler. Subsequently, the material is introduced into the roll forming machine.

Roll Forming

The core of the machine comprises a sequence of rollers that progressively bend and shape the metal strip into the U-shaped profile. Each roller set is meticulously engineered to attain the specified dimensions and characteristics of the U channel.

Cutting

After the metal strip has been shaped into the U configuration, a cutting mechanism, such as a flying cutoff or a post-cut shear, is employed to sever the profile to the required length. This guarantees that the final product meets the correct specifications

Stacking

Once the U channel has been formed, cut, and any essential post-processing steps have been finalized, the completed pieces are generally stacked, bundled, or packaged for convenient handling and transportation.

U Channel Roll Forming Machines are available in a range of sizes and configurations, tailored to the complexity of the U channel profile and the necessary production volume. These machines can be either fully automated or semi-automated, based on the required level of precision and efficiency in the manufacturing process.

U Channel Roll Forming Machines play a crucial role in industries that demand consistent, high-quality U channels for diverse applications. They provide benefits such as cost-effectiveness, repeatability, and the capability to produce U channels with various dimensions and features to satisfy specific project needs.

All roll forming machinery is completely assembled at our factory. Our Roll Forming Machines include a one-year warranty covering parts and labor. Each machine will be customized to meet the individual requirements and profile of the customer.