The standing seam machine serves as the essential equipment for producing standing seam roofs. It employs advanced roll forming technology to transform metal sheets into panels featuring continuous vertical seams.

Profile Size:

1.Height of Roofing: 65mm;

2.Effective Width: 400mm, 425mm;

3.Material Width: 575-578mm for 65/400,600-603mm for 65/425,

4.Thickness for Aluminum Sheet: 0.9-1.2mm;

5.Thickness for Steel: 0.7-0.9mm;

6.Min. Width of tapered roofing:250mm;

7.Max. Width of tapered roofing:450mm(only for the machine to install in the container);

8.Min.Length of tapered roofing:1000mm;

Specifications:

| Type | YX65-400 |

| Material Width | 575-578mm |

| Height of Roofing | 65mm |

| Effective Width | 400mm |

| Thickness for steel | Q235-Q345(steel):0.5-0.8mm |

| Thickness for aluminum | (Al-Mg-Mn):0.7-1.0mm/0.9-1.2mm |

| Forming steps | 13Steps |

| Dimension | 5800*1600*1400mm |

| Motor Power | 7.5KW*2 sets |

| Hydraulic Power | 2.2KW |

| Forming Speed | 8-14m/min |

| Voltage | 380V/50HZ/3PH |

| Weight | 7000KGS |

| Control System | PLC Control |

| Control System | 1set, PLC (Delta), Touch Screen (SCHNEIDER), Inverter (Delta), Encoder (Omron) |

| Material of rollers | 45# steel |

| Configure | Machine、3Pcs Run Out Table、5 Tons Manual Uncoiler、Auto Seamer、Hand Seamer |

The standing seam machine serves as the essential equipment for the production of standing seam roofs. It employs advanced roll forming technology to transform metal sheets into panels featuring continuous vertical seams.

This design significantly boosts the structural integrity of the roof while also enhancing its waterproof capabilities. Numerous models and specifications of these machines are available in the market, such as the Standing Seam Roll Former and the Standing Seam Forming Machine, which cater to the diverse requirements of various projects regarding the dimensions, shapes, and thicknesses of roof panels.

For manufacturers in search of effective production solutions, information regarding Standing Seam Machines for Sale is certainly a valuable resource.

Whether considering a brand new roof seamer machine or a pre-owned standing seam panel machine, the market offers a wide array of options. While used equipment tends to be more cost-effective, it is essential to thoroughly inspect the condition of the machinery prior to purchase to ensure it meets production standards.

For particular design styles, such as snap lock metal roofing, specialized snap lock standing seam roll forming machines are available in the market. These machines are capable of producing roof panels featuring a distinctive locking mechanism. This design is not only aesthetically pleasing but also provides enhanced stability, making it suitable for structures in harsh weather conditions.

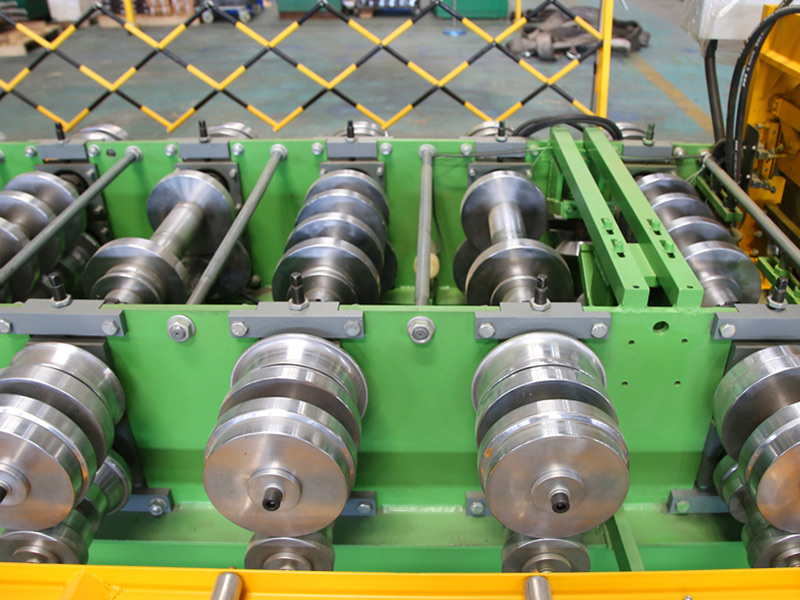

Roll Forming Device

Rollers that have been thickly chromed and quenched to ensure optimal hardness and resistance to abrasion

1.Forming Steps: 13

2.Working Speed: 8-14m/min

3.Roller material: high grade 45# forged steel,Plated Hard chrome and polished all the rollers

Cutting Blade

No need to change blades for different sheet widths

1.Cut-off system: Hydraulic cutting device

2.Material for Blade: Cr12 mold steel with quenched treatment 60-62°C

Control System

Electronic components including PLC, inverter, and touch screen are from SCHNEIDER or other customized brands.

PLC Computer Controlling System With Touch Screen ( Brand: Delta )

Application:

Standing seam roofing systems are recognized for their durability, resistance to weather, and contemporary architectural attractiveness. The profiles of standing seams not only establish an aesthetically pleasing design but also offer practical advantages, including effective water drainage and leak prevention. Furthermore, the concealed fasteners and seams hinder moisture penetration, thereby improving the roof's overall weatherproofing.

In summary, standing seam profiles are a hallmark of standing seam metal roofing and are widely favored for various architectural and construction purposes.