Specifications:

| Type | KSL25-220-530 | KSL38-220-530 |

| Material Width | 290-600mm | 290-600mm |

| Height of Roofing | 25mm | 38mm |

| Effective Width | 220-530mm | 220-530mm |

| Thickness for steel | 0.5-0.8mm | 0.5-0.8mm |

| Thickness for aluminum | 0.7-1.2mm | 0.7-1.2mm |

| Forming steps | 6Steps | 8steps |

| Dimension | 1800*1200*1000mm | 2000*1100*1200mm |

| Motor Power | 1.5KW | 2.2KW |

| Hydraulic Power | 0.75KW | 0.5KW |

| Forming Speed | 8-15m/min | 6-8m/min |

| Voltage | 380V/50HZ/3PH | |

| Weight | 150KGS | 1500KGS |

| Control System | PLC Control | |

| Control System | 1set, PLC (Delta), Touch Screen (SCHNEIDER), Inverter (Delta), Encoder (Omron) | |

| Material of rollers | 45# steel | 45# steel |

| Configure | Machine、3Pcs Run Out Table、5 Tons Manual Uncoiler、Auto Seamer、Hand Seamer | |

Overview of portable standing seam roll forming machine:

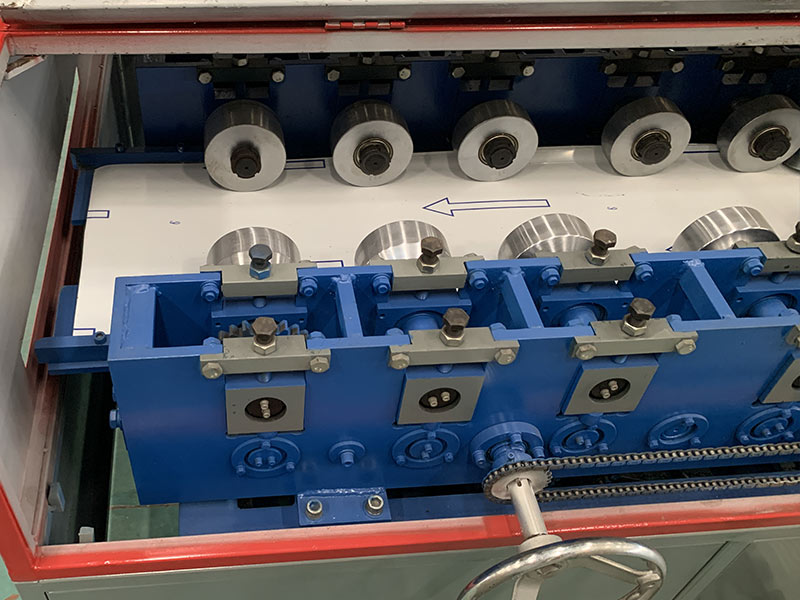

Roller

1.Roller material: high grade 45# forged steel, plated hard chrome and polished all the rollers

2.Forming Steps: 6steps

3.Working Speed:10-12m/min

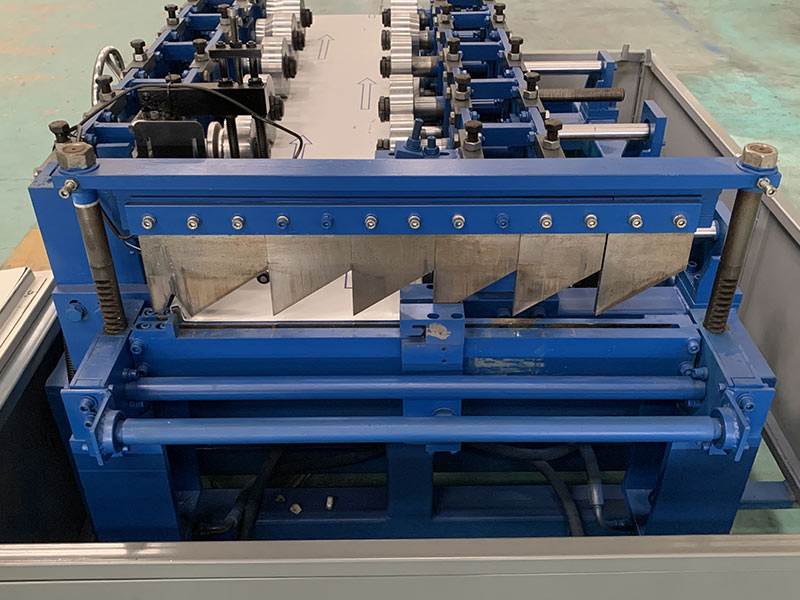

Cutter

1.Cut-off system: manual cutting device

2.Material for Blade: Cr12MoV steel with quenched treatment

What makes the machine portable?

It is not solely the dimensions or mass that render the machine portable for job sites. Additionally, the overall design indicates ease of transport and resilience to challenging road conditions. The profiling unit can be easily detached from the frame.

How it Work?

Now, let us examine the process by which the metal is passed through the rollers to achieve the desired final shape. By simply turning a handwheel, you can effortlessly adjust the width from 290 mm to 600 mm. The handwheel's rotation causes the shaping rollers to move in unison.

The rollers are the most impressive feature of this machinery. Not only do they include gauging rollers that assist in attaining the required thicknesses or stiffness, but there is also the option to add extra rollers for creating semi-round or trapezoidal ribs. Furthermore, due to the use of composite rollers, there is no risk of damaging the polymer coating. At one of the concluding stages, the panel passes through the final straightening station, after which the shaped product is cut to the specified length using a shear or guillotine.

A protective cover is in place to eliminate any risk of injury from the machine.